From: Brian O’Connell [mailto:cbrianoconnell@gmail.com]

Sent: Tuesday, July 19, 2011 7:43 AM

To: xxx@neo.tamu.edu

Subject: Bodrum Tirhandil Project

Dear Professor Bass,

My name is Brian O’Connell. I am an artist based in New York. I am currently in Turkey planning a project meant to take place in the next year. I’m interested in the way that forms, ancient and contemporary, carry known and sometimes unknown records of their cultural and structural antecedents. In the spring of 2009 I made a 13 foot functional cement hull in Los Angeles (see: http://boconnell.org/ART/BOAT/Boat1.html). The form of this hull was based on that of an earlier boat used by Dutch artist Bas Jan Ader in 1975.

My current project involves a much more complicated history that I am hoping you may be able to lend some insight into. I’m currently looking for a disused and or no-longer seaworthy 9-10 meter boat in or around Bodrum. This boat will be used as a mold for a “new” concrete vessel which will bare the impression of the old structure on its inside surface.

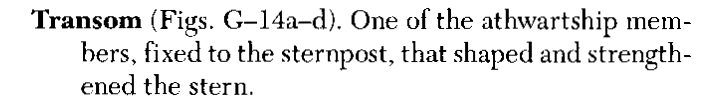

I am hoping to find a tirhandil which according to some internet sources (I’ve been unable to find reliable literature on this subject) dates back some 2500 years. Apparently Tirhandil are the oldest form (and shape) of boat still used in the region. Furthermore, the name is said to derive from Greek for 3 to 1. Based on the working boats I’ve seen while here this seems plausible but I’m wondering if you have any ideas about whether or not this is true and where I might look to better source such claims. I also found it interesting and encouraging to note that many of the wrecks – e.g. that at Bozburun (15 x 5 m) – have similar proportions.

This form and its history (if true) is of particular interest to me because like ancient Greek sculpture, proportion directs all the boat’s dimensions. If one could start with a single dimension and go from there just as ancient mathematicians did (after all Pythagoras couldn’t and didn’t need to calculate Pi as long as he could define and use it) the implications for how form is transmitted over time and across cultures and disciplines are fascinating to me as an artist.

Thanks you very much for your consideration and I look forward to hearing any suggestions you may have.

All the best,

Brian O’Connell

_______________________________________________________________________

Brian O’Connell / www.boconnell.org / 436 Willoughby Ave, Brooklyn, NY 11205 / tel. +1.917-553-4227

I left for Istanbul via Paris in mid-July. When I took this picture I had no idea of the closeness of the machine I was about to board to the ancient technologies for which I was setting out in search.

I spend my first days back in Istanbul walking the city looking for the boat shapes I had previously overlooked, and about which I have only read bits and pieces online.

It will be explained to me not more than a week later that boats with transoms* are relatively new and may only have been designed to accommodate the extra burden of cannon used in sea battles. I am unable to verify this and it seems that transoms were present on the great ships of the Ming Dynasty’s Zhen He when he embarked on the first of seven westward expeditions in 1405, as well as the re-rigged caravela latina Nina, which Columbus sailed eighty-seven years later.

*

Beginning at the boat supply shops of Karakoy, I cross the Golden Horn on a small wooden ferry powered by a loud two-stroke engine that bobs wildly in the wake of the low cruisers that crowd the river-like estuary. Nonetheless the boat seems surprisingly stable and I wonder if, with its symmetrically pointed bow and stern, it shares a common ancestor with the tirhandil, the search for which has brought me to Turkey.

I make my way along the shoreline from the Old City to the cafes of Bebek.

Walking back toward the bustle of Besiktas, men roll long lines dotted with tiny hooks into bready balls before casting them far into the fast-moving, blue-green water of the Bosporus. Moored along this stretch is a mix of speedboats; yachts sailing under the flags of many nations; and hulky boats done up to look like Ottoman and Byzantine ships, rented by the hour for pleasure cruises, birthdays and weddings. Among these are the small wooden boats used for fishing and other waterbourne work.

A group of men pull one of these boats out of the water using a winch attached to a cable slung under and around the hull. As it jerks onto dry land I notice the sturdiness and bulk of the keel on which it now stands.

I am looking for what has been described as the characteristic double-ended hull of the tirhandil, but in the half day I spend looking at boats it seems that almost all traditional boats come to some sort of point at both ends.

Obviously overlooking some finer subtlety, I give up my search for evidence of tirhandil. They are not native to Istanbul. Taking the ferry across the Bosporus to the Asian side of the city, I continue my walk back up the opposite bank of the strait. The same scene of fishing lines being cast and small boats at anchor plays out. It seems equally useless to ask about boats and their shapes using the one nautical term I know in Turkish. To my surprise, the only shop whose sign I can decipher seems like a promising place to begin a less anecdotal approach to my search.

Unfortunately the store is closed and when I return the next day the shopkeeper directs me to a publisher of nautical posters who may have more information.

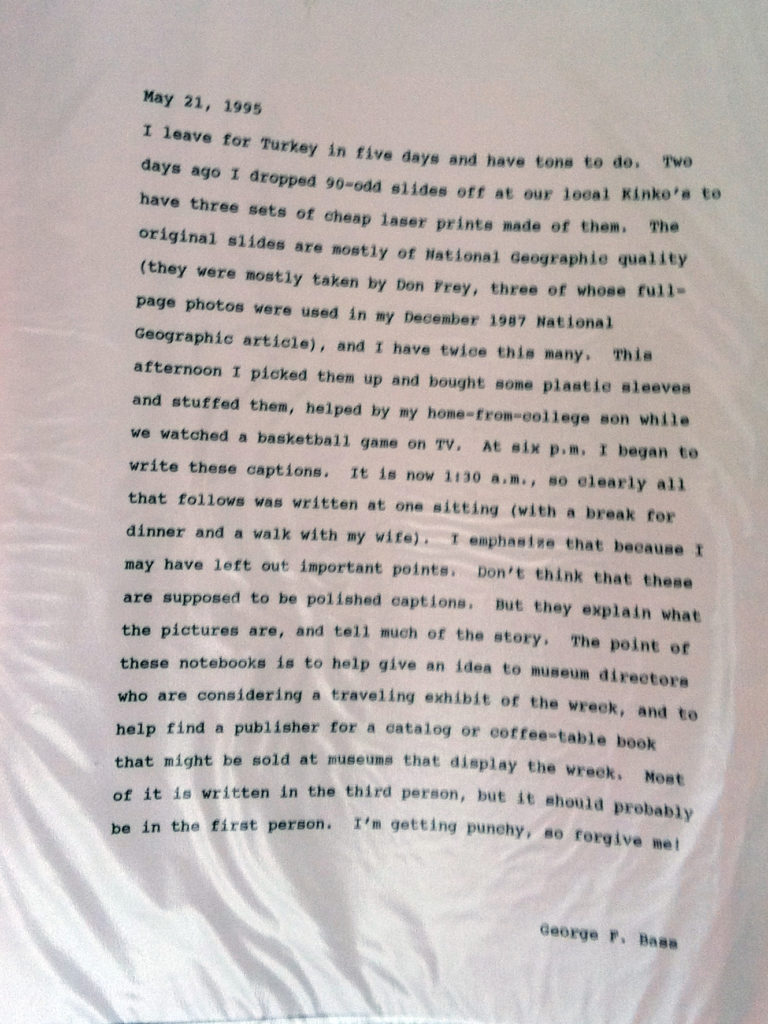

I spend my last day in Istanbul following this and other fruitless leads. That night in a bit of a panic I email Prof. George Bass of Texas A&M University.

Hello Brian,

George Bass forwarded your email to me since I am living in Bodrum and might be able to help you. He and I have worked together underwater since 1969. However my own degrees are in physics so I am much better on Pythagoras and Pi than I am on ancient or modern hulls.

But our local craftsmen have been building wooden boats for much longer than I have been here and our shipyard now has an international reputation. So probably I can help you find someone from the ‘old school’ still around, although they probably won’t speak English.

So if you do decide to come to Bodrum let me know when and I’ll be happy to try to find you a few contacts.

<CIMG1096.jpg>

<CIMG1098.jpg>

<CIMG1090.jpg>

Best regards,

Don Frey

The next morning I fly to Bodrum where my search can begin in earnest.

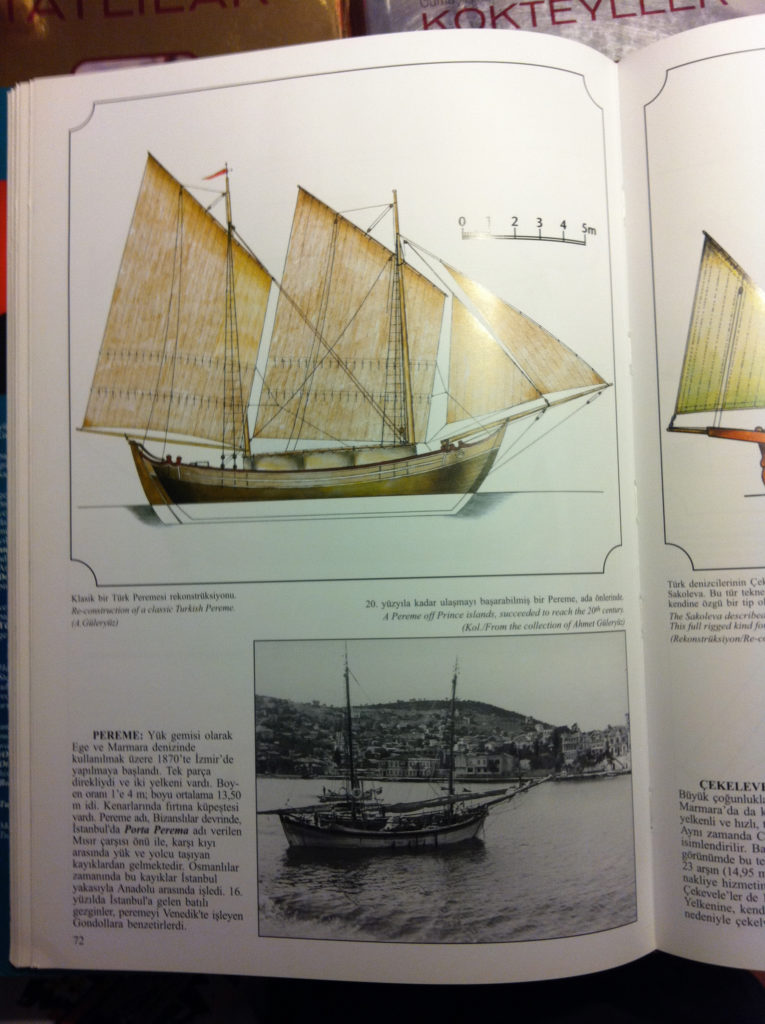

I find this hull by the side of the road between Yalikavak and Genusuluk (ancient Myndos).

On my first full day on the Bodrum peninsula I drive along the coast looking for the barn-like structures in which non-commercially built wooden boats are often made over the course of years as money, materials and labor become available. I have seen these buildings before but cannot remember if they are common or if I have allowed one distinct memory to grow into many. Bolstered by the luck of finding a deteriorating boat opposite a carpenter’s shop I begin looking at every stack of wood I come across, often taking my eye off the road longer than advisable. Within less than an hour what in Istanbul seemed unlikely begins to take on a feeling of clear possibility, though I still have not seen what I believe to be a tirhandil, in or out of the water.

Coming across a small(2.58m) wooden dinghy lodged in a pile of what appears to be scrap wood in front of a cabinetmaker, I stop to look at it and am told it is for sale.

I agree only half-seriously to come back the next day after initial gestural descriptions of my plan to cover it with cement seem insufficient. I ultimately settle on an explanation that I am interested in using it as a garden planter.

I continue to Bodrum’s main shipyards, where boats of all description lay apparently abandoned among the enormous sheds in which the mega-yachts for which Bodrum is increasingly known are built. Among these is the dilapidated hull of an old 9-meter fishing boat – still not a tirhandil. “For Sale” is painted across the transom in fading whitewash.

As I leave the shipyard, I come across two boats under construction. At last I have found the double-ended, almost bloated form of the tirhandil. The contrast between the structure outlined by the steel frame of one and the smoothly articulated form of the resin-coated wood of the other is striking.

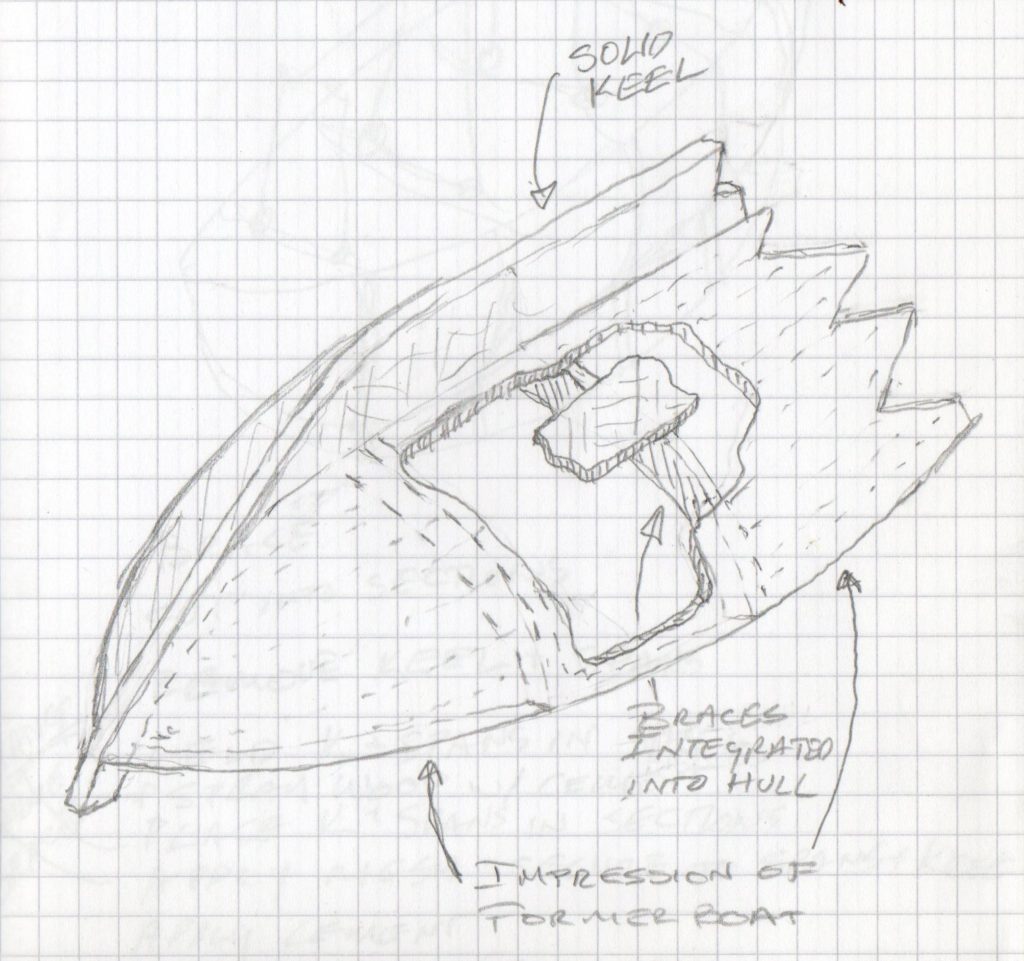

I have been thinking for quite some time how the frames used to support an eventual cement cast might be integrated into an existing boat’s hull. I decide what I already know: I will have to make a prototype using the dinghy still lodged in the woodpile at the cabinetmaker’s.

The next day is spent investigating the availability of materials as I wait for the small boat to arrive.

From: George F Bass

Sent: Wednesday, July 20, 2011 9:21 PM

To: ‘Brian O’Connell’

Subject: RE: Bodrum Tirhandil Project

Dear Mr. O’Connell,

It may sound strange, because of my reputation for excavating old shipwrecks, but I am the last person to answer your questions. In the earliest days, half a century ago, I worked with Peter Throckmorton, who knew so much about traditional Mediterranean watercraft that I began to concentrate only on the contents of the vessels, and always left the study of their hulls to others, more expert and more interested than I could ever have been. How I wish that my colleague of many years, Dick Steffy, were still alive, for I know he would have so much to say on the subject (do you know his book Wooden Ship Building and the Interpretation of Shipwrecks?).

I’ll forward your message to a number of colleagues who may be able to respond. If any one of them has anything to say on the subject, I am sure you will hear back.

Alas, a stroke in January means I may not get back to Turkey again, a country I first visited in 1953, and where my wife and I built a house.

Good luck with your project,

George Bass

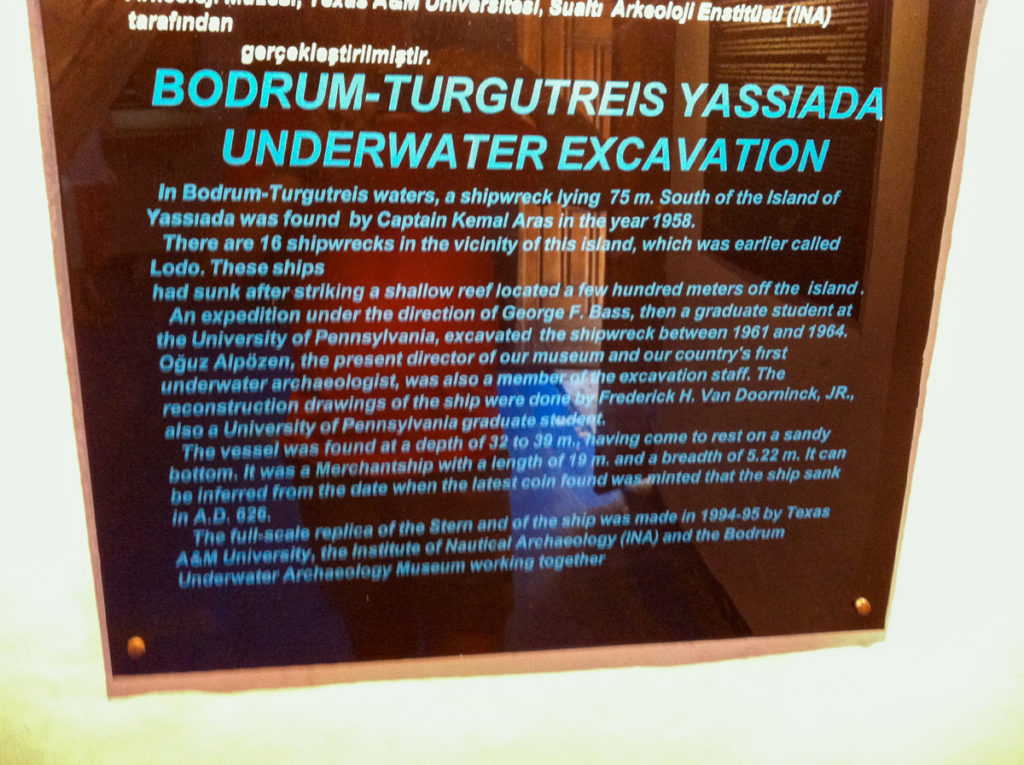

Before tackling the practical problems posed by the prototype I hope to find some sort of evidence for the claim that tirhandil descend from a line of ancient boat forms, so I pay a visit to the Institute of Nautical Archeology (INA) run by Texas A&M University in Bodrum. Archeologists associated with the INA have excavated sunken shipwrecks in the region since the late 1950s, when Peter Throckmorton, then writing a magazine article about sponge-divers for whom the tirhandil was a favorite diving platform, was told by a local fisherman of his plan to use dynamite to salvage a sunken pile of copper near one of his sponge-diving grounds. Convincing the man to wait yet another season before continuing with his plans, Throckmorten contacted George Bass, then a graduate student at the University of Pennsylvania. The following summer, Bass and a ragtag team of archeologists began exploring thYassi Ada wreck – in the first professional underwater use of archeological methods. Beginning with this operation, Bass and a growing team of archeologists developed methods of underwater excavation that not only revolutionized our understanding of the ancient Aegean but also the technologies used in constructing boats as long as 3,ooo years ago. Many of the practical questions that I am trying to avoid by spending a day in the air-conditioned comfort of the library will be answered by these technological discoveries.

Placing a stack of books on the desk, Nurgul, the librarian, admits there is very little here about contemporary shipbuilding – this is after all an archeological institute. Unsure where I may find any connection between ancient boats and boats still being made, she introduces me to John Littlefield. John, a graduate student of nautical archeology, believes the claims I have read about tirhandil may be based on a 1964 article by Throckmorten, but hints that they are likely more about marketing than historical fact. He notes that from a technological perspective nothing particularly new was invented until the last century, when we see an explosion of novelties. His prime example is the claw hammer that has remained relatively unchanged since ancient times. Similarly, he says, there are really only a few shapes a boat can take, and tirhandil look pretty much like any number of ancient boats. Here our discussion turns from form to structure, specifically how boats are built. Asking me to wait a moment, John runs out of the room. He returns with a large section of milled timber.

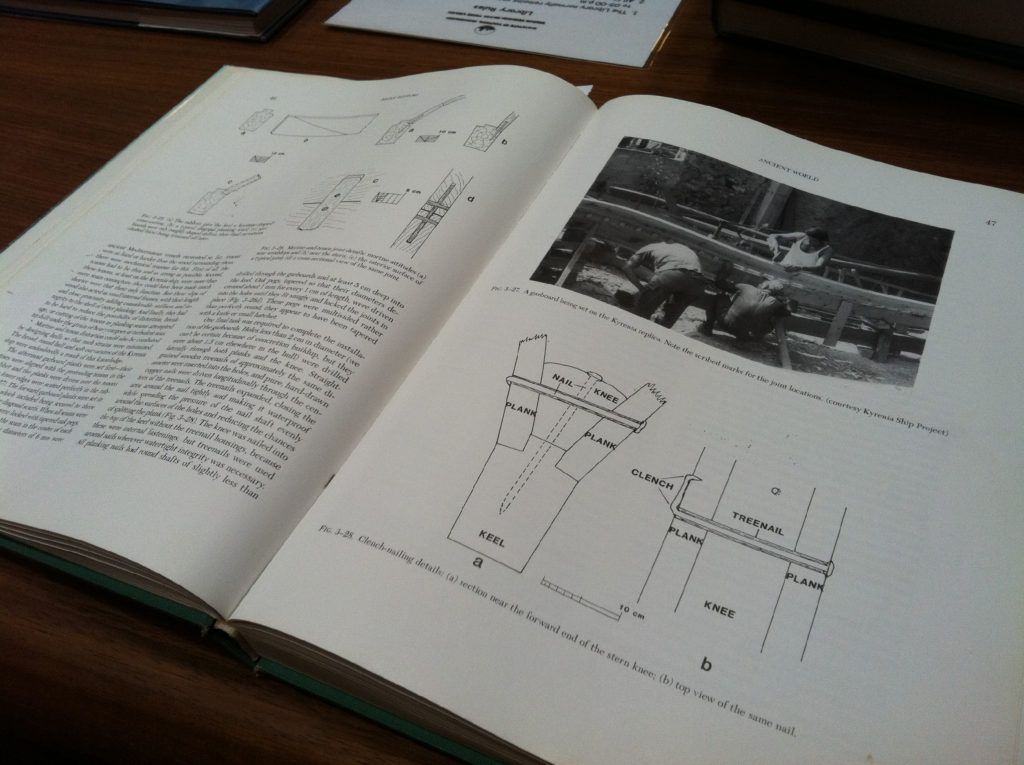

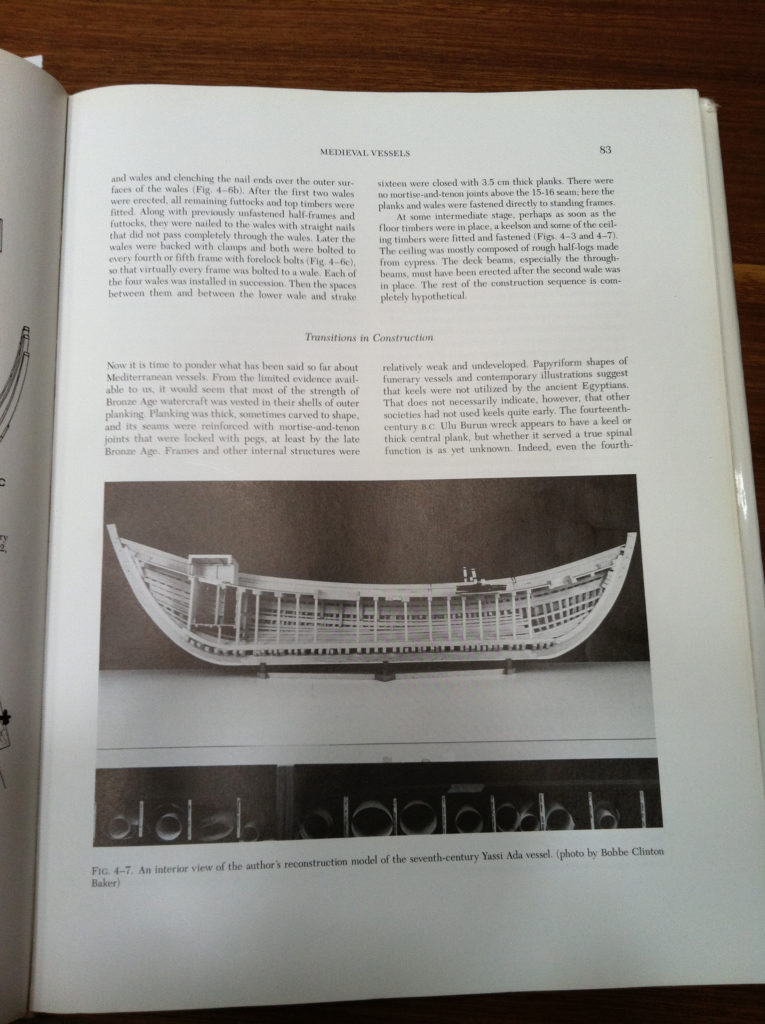

It had always been assumed that ancient boats were more or less constructed in the same way that contemporary ones are: a series of frames are built that represent the shape of the hull, and then planks are wrapped around these frames, making a watertight barrier that allows the boat to displace enough water to float.

Hull fragments excavated at Yassi Ada and subsequent sites show this assumption to be completely wrong.

Though as little as 10-20% of many of these wrecks’ hulls remain, careful reconstruction and full- and small-scale replicas show that rather than beginning with frames, ancient ships were built longitudinally. Beginning with the keel, strakes* and planks were added along the length of the boat to form a shell (frames only being added later to provide extra stability). Such boats have even been shown to be superiorly watertight due to the precision of the joinery necessary to make them. The distinction between frame-first and shell-first construction is the principle ground for John’s unequivocal opposition to the idea that modern tirhandil are ancient boats. It also suggests a possible solution to my framing problem. Would it be possible to more or less reverse the historical trajectory? If a cement hull were strong enough to support its own weight, couldn’t frames be added later? John is unsure but offers to show me the labs where objects – including hull fragments, tools, fasteners and cargo – are prepared and preserved. I follow him to the basement of the institute.

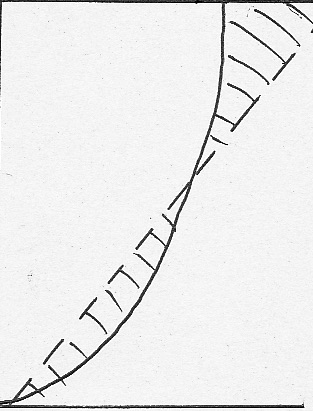

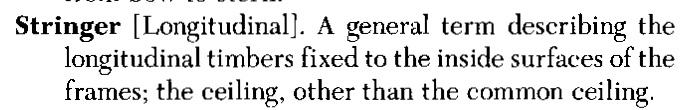

*

This apparently iron hammer is not the hammer used by an ancient mariner. Rather, it is a resin cast of the space left in a concretion of calcium around the original iron that has long since disappeared. The color and texture left by the former object produces an uncanny sense that this is more than the end of a very long mold-making experiment. I wonder how this shape differs from the original held 2000 years earlier or that 20 miles away in my tool box.

When recovered from the sea floor concretions are x-rayed.

Resin is injected into the gaps revealed by the x-rays and the positive form is broken out of its calcium mold.

Among the concretions and hull fragments thousands of amphora are recovered from the wrecks. Most often only terra-cotta shards remain. A team of experts pieces together these vessels, filling gaps first with wax, then plaster. It seems impossible that they know what goes where.

I anxiously expect the arrival of the dinghy in Gundogan, to which I hurry home. Along the way, I pass a favorite site: a modernist structure, perhaps a school, built into the hill below the road. A tree grows directly through the flat roof, its trunk rising from the earth two stories below. It is unclear if the building is built around the tree or the tree has simply ignored its attempted architectural subjugation. I like to think the latter. Imitation amphora lie for sale on the side of the road. The dinghy arrives as planned in the back of a pick-up truck.

Hi Brian,

No worries for yesterday. I enjoyed learning about what you are doing. It’s a very interesting project.

I will attempt to answer your questions in list form in order to avoid confusion in my own mind and keep me on track LOL.

1. Is this article’s claim about these boats in fact being the successors of ancient hull shapes and there geometry out of date given that it was published in 1964?

answer: somewhat yes. I don’t mean to be vague but the geometry is very similar as you are aware, but ,as we discussed, construction is very different.

2. Had the shift from shell first to frame first construction yet been discovered?

answer: short answer…no. At that point, very little ship’s hull remains had been discovered, recovered, or studied. In 1964, Dr. Bass and his team were in their third year of excavations of the Yassi Ada 4th c. Roman wreck. I cannot say for certain, but I seriously doubt that they were close to even knowing that the shell-first construction style was a cultural tradition at that point. As far a discovery of the date of transition is concerned, that came much much later and in some circles is still debatable (some time between the 4th and 9th centuries, with the 7th c. being most popular at this point)

3. If not from an archaeological perspective would it be possible to make the claim laid out here about the form regardless of the technology used to produce it?

answer: I do not believe so. For example… If you make a concrete boat to mimic the tirhandil, then it’s geometry is also the same, it’s function is the same, but it’s construction is very different (as well as the materials). There is likely a better analogy than this, but I think you will get my point.

Then again, if the visible end product looks similar, then perhaps the argument holds water.

I hope this helps. Feel free to write again or stop by the institute.

Best,

Joh

Bringing the dinghy down to a vacant lot, the first step in preparing it as a mold will be a reversal of its construction. This requires removing the keel.

After applying a thin coat of boat varnish to all surfaces to be cemented, I assemble my supplies and begin tests with cements, wire meshes and the floor soap that I hope will act as a release agent between the wood and the cement.

The heavy stock of the false keel* removed, the protruding section of sternpost and a section of the bow are sawed off, making a flat bottom for what will become the inside of the cement cast. The sections are kept to be copied in cement and added to the final form.

After applying a thin coat of boat varnish to all surfaces to be cemented, I assemble my supplies and begin tests with cements, wire meshes and the floor soap that I hope will act as a release agent between the wood and the cement.

An initial layer of white Portland cement, sand and water (in a ratio of 3:3:1-1.5) is spread over the test area to pick up as much detail of the hull as possible. A layer of wire mesh is laid into the surface of this first coat to assure that the subsequent structural layer will adhere to this crucial internal layer.

Having been kept wet overnight, the first layer has cured. Three layers of chicken wire and a final layer of mesh are put in place.

Heavier cement is pressed through the wire layers to produce a strong though flexible steel and concrete outer layer. After curing, the sample is removed and kept wet as long as possible.

Hi Brian,

I just talked to Xila (Sheila) Matthews who did most of the reconstruction of the Glass Wreck hull and more recently has been involved in the excavation and recording of the Byzantine ships discovered at Yenikapi in Istanbul. She mentioned to me that one thing which might interest you is the three dimensional images she has of several of the Yenikapi hulls. She works at the Institute so you could meet her there (but she is away for gym classes sometimes – so call first). Her cell phone number is 532-4179543.

It was fun to spend the evening with you and Mary……I’m glad you made it home without any problems!

Remind me when you return to Istanbul so that before that we can do a boatyard trip.

ABRAZOS,

Don+

I spend an evening with Don Frey and his wife, Suzanne, over which they recount their lives in Bodrum, which has transformed from a village of 2,000 to its current status as a summer tourist mecca with a year-round population of nearly 35,000 inhabitants. In the morning I return to the INA while additional tests cure. The Institute now feels more tangibly about the lives of those who work here than ancient history.

Cement hulls must be produced in one go. The process must be continuous. On larger projects popular among DIY builders since the 1960s this requires plastering parties where groups of friends are drafted into an all-night sessions pressing and smoothing heavy mortar. It is important that everything be in place before beginning this process.

I plan to embed cabinetry nuts in the cast to secure frames to the inside of the hull. I remove some existing frames, drill through the skin and place bolts to hold the nuts, and eventually the frames, in place. Before proceeding I have an appointment with Xila (Sheila) Matthews at the INA. Given her expertise in reconstruction I hope she will be able to help me think through building a boat in reverse. Xila has reconstructed and built many of the wrecks and models in the INA museum at the Castle of the Knights St. John, which dominates Bodrum’s harbor.

The Knights Hospitaller built the Castle beginning in 1402. Much of the material used was taken from the now ruined mausoleum of Maussollos. It was these ruins, rediscovered in the 1960’s, that brought Don’s wife, Suzanne, to Bodurm as a young archeology student. Maussollos’ tomb was one of the seven ancient wonders and is the origin of the word mausoleum. Most of its stone was burned to make lime for mortar and plaster. The castle now houses the INA’s most significant finds and reconstructions. Intact parts of the mausoleum used by the knights were brought to the British Museum in the mid-19th century. The Castle, always an architectural palimpsest, now holds 3,000 years worth of materials brought to the surface since 1962 by, among others, Don, who now gives tours.

Leaving the museum I return to the shipyards to see if any signs of tirhandil have emerged since my initial visit three weeks earlier.

This former Greek lifeboat is undergoing a most literal retrofitting that will transform it from a utilitarian fiberglass shell into a now fashionably old ‘wooden’ tirhandil.

The Greek name is still visible, but not for long. Tirhandil seem to be gaining popularity as hobby boats. A group of young men have been working on this beautifully reconstructed example in Gundogan Bay, though I have not seen it under sail.

Having seen the results of two generations of archeologists working on millennia of submerged wrecks, I return to my little vessel imagining that it and the operations I am undertaking are being applied to the much more ambitious project that has remained an illusive but increasingly committed goal. I try to estimate the weight and displacement of my boat and that of an eventual 9-meter tirhandil. This requires calculating the surface area of the hull. I email Don, whose background as a physicist should make this a relatively simple problem.

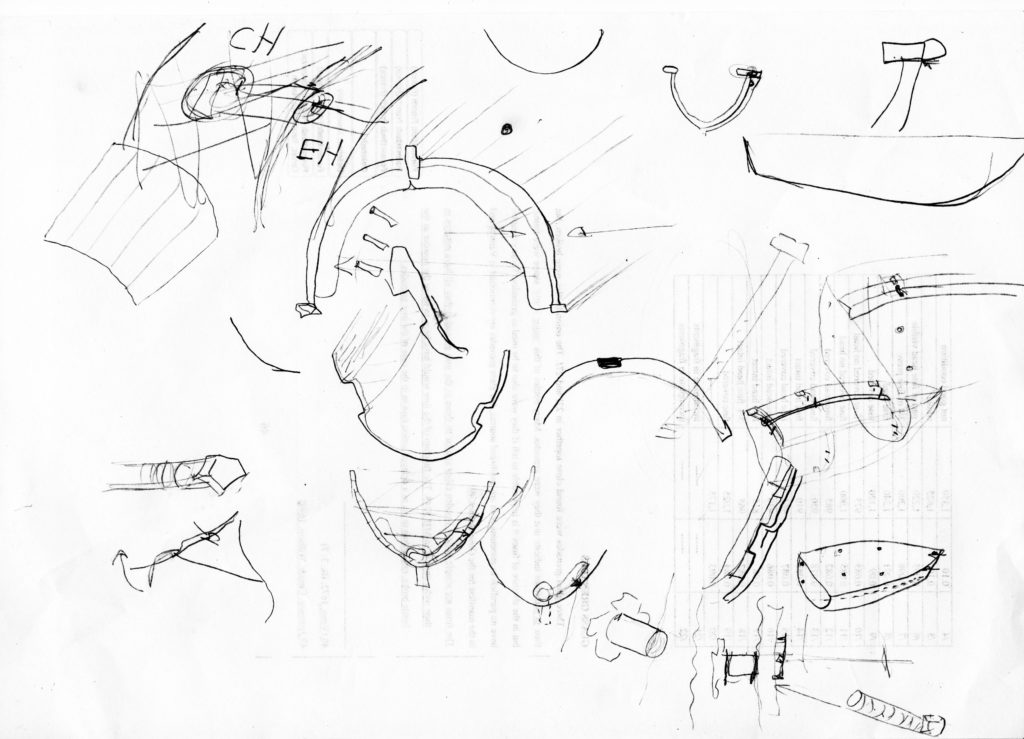

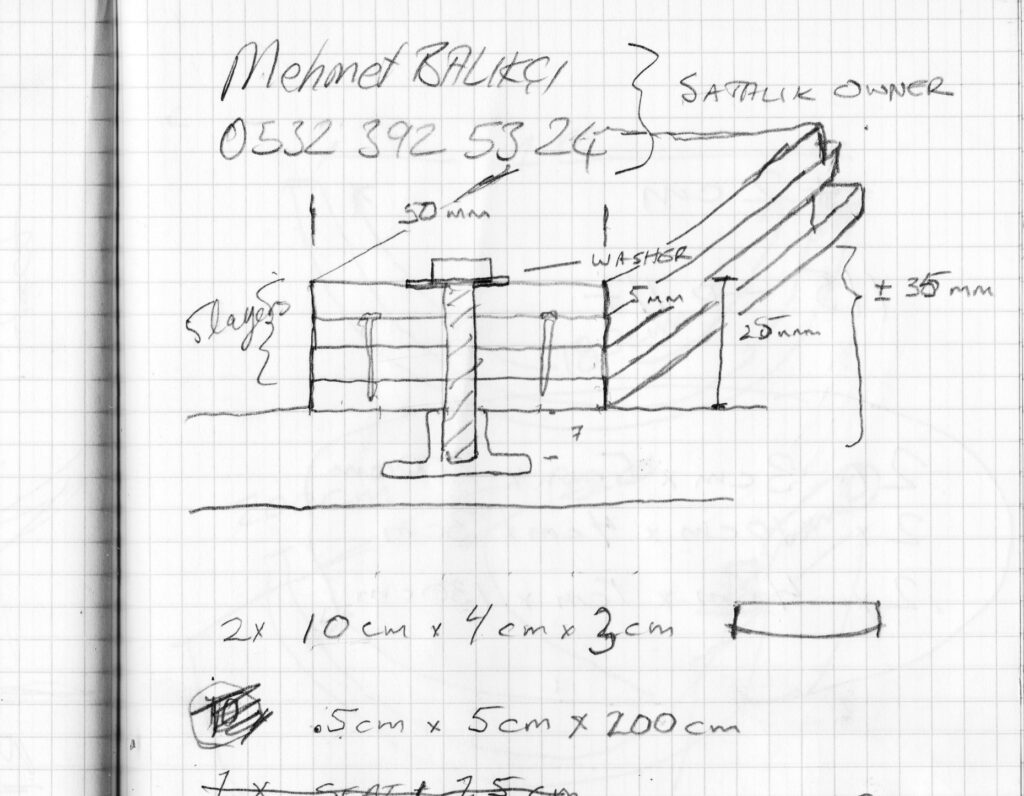

Deciding that this problem will resolve itself without my attempting complex mathematical procedures, I instead meet with Xila. At this point I realize I’m delaying what I know will be a labor-intensive and determining period. We spend the afternoon trading drawings working out how my plan may work for a larger boat. She points out that my concern should be less whether a 9-meter ferrocement hull will be seaworthy and more how it will stay deep enough in the water without added ballast. She explains that frames and stringers* assure that the form does not twist under sail, and provide actual strength. This means that an eventual cement hull may need very few if any frames but will need to be braced longitudinally.

A 9-meter boat may only require two frames: one at midships** and one at midkeel to act as attachment points for two sets of stringers, and/or a caprail.***

As we finish our conversation, Xila tells me about a man who lives in a wooden house above Gundogan. His name is Mustafa – Captain Mustafa. Having spent his professional life sailing the Forsa, a large green charter out of Bodrum, he would be able to help me technically, and, most importantly, he knows everybody who has anything to do with boats on the peninsula. The only problem is finding him. As I return to Gundogan I scan the ridge but cannot see a wooden house. The next day I will begin applying the same procedure to the entire boat that I did in the earlier tests. This will take three days.

*

**

***

The finished hull receives a steel plate along the bottom of the keel to protect it from damage when the boat rests upright on the ground.

A cement caprail is added to finish the top edge.

The inner hull can now be removed. It has been crucial not only as a mold but also as a support during the precarious and volatile process of flipping and righting the heavy but fragile, 400-pound, 3/4-inch thick shell.

Removing the sternpost proves the easiest part of the de-molding process. It also offers a first glimpse of the new hull’s surface.

Removing the frames is the first and most difficult part.

The surface begins to be revealed.

Going to a local cabinetmaker, I describe my project using diagrams made at home and images taken with my phone. We settle on a plan to use strips of flexible plywood that will bend to the shape of the hull as they are screwed into place. Once glued together the laminated frames will hold their shape. Thin strips that will be attached to the frames to act as partial stringers and support the seat are cut from a large piece of hardwood.

All the materials are ready to finish the boat and test the shell-first design that will be used on the larger project.